Bespoke Shirt Maker

J.H. Cutler Bespoke Shirt Maker delivers the finest shirts in the world, made to each client’s unique specifications. Founded in 1884, and directed by Sam Hazelton since 2010, we create shirts of distinction, combining the world’s finest fabrics and an uncompromising approach to fit and style with artisanal craftsmanship.

Bespoke Shirt Making

The bespoke process begins with a conversation. Clearly understanding your requirements is paramount if

we are to create garments that are tailored to your lifestyle, and we know what to ask.

A comprehensive range of fabrics, any conceivable style or fit, and an unsurpassed attention to detail, function and comfort allow for almost limitless possibilities.

Pricing & Orders

Single-needle machine sewn bespoke shirts are priced from $550.

Hand-crafted bespoke shirts are priced from $850.

Minimum order of three shirts for your first order.

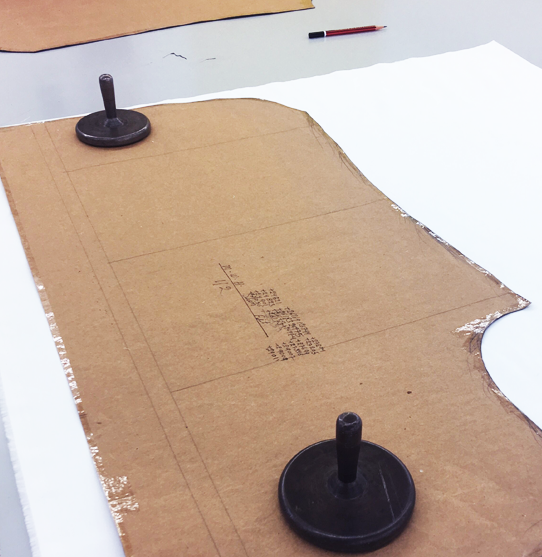

Two elements that make the process distinctly bespoke are a pattern hand cut from your measurements, and a series of fittings, generally two, through which we achieve the best possible fit for each individual. A fitting shirt is made from your pattern to assess its accuracy prior to making the first of your bespoke shirts.

Once the required fit has been achieved, your first shirt is made from the correct fabric to the finest artisanal standard. The updated pattern and the final specifications of your unique style are retained in order to streamline future orders and ensure continuity of fit and style. J.H. Cutler bespoke shirts can be made via two varieties of artisanal craftsmanship, being single-needle machine sewn, and fully hand sewn.

Single-Needle Craftsmanship

the optimum density combining strength

and aesthetic refinement.

with superfine 2.5mm seams, rolled and pressed by

hand before being machine stitched.

inside the collar and cuffs, for crisply fused

or natural un-fused construction.

collar and cuff of every J.H. Cutler bespoke shirt.

the junction where 4mm hems intersect

with 2.5mm side seams.

The junction where 4mm hems intersect

with 2.5mm side seams.

Hand Made Craftsmanship

topstitching defines the edges of placket, collar and cuff.

stitched by hand before the sleeve is inserted

and secured with an almost invisible hand stitch.

the bottom edge of the shirt, and completed

with the application of a hand-folded gusset.

and hand sewn in place with bar-tack reinforcement.

by hand with silk thread.

stitched to the sleeve and neckline by hand.

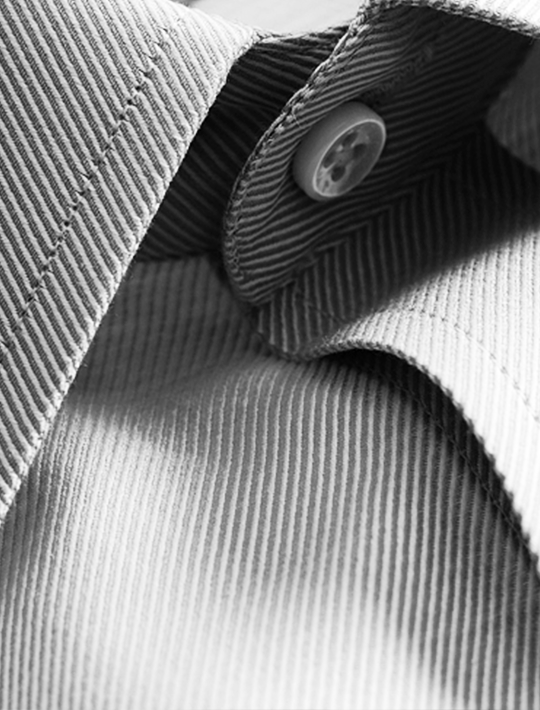

Shirting Fabric and Trims

More than a century of experience producing bespoke shirts for men gives us unique

insight into the performance and characteristics of many shirting fabrics available today. We source

fabrics from a small number of the world’s best producers, selected for their creativity, expertise and excellence.

Natural fibres, from sturdy heavier weights to ultra-luxurious light weights and casual classics like linen, cashmere

and denim, are expertly handled to create men’s shirts for any dress code or occasion.

Looking for a specific fabric? Email us with your enquiry

Provenance

a presence since the late 1970s, they have built a community of valued and

loyal employees, fostering a culture of unparalleled expertise in textile

production and craftsmanship.

J.H. CUTLER EST 1884

With a wealth of knowledge and expertise from four generations of genuine bespoke tailoring, we create timeless sartorial goods that are exclusively hand-made for each individual customer, with the finest artisanal craftsmanship.