Our Craft

Consistently dedicated to the highest level of bespoke craftsmanship since 1884,

we have developed a practice that upholds and promotes artisanal techniques and values,

whilst responding to the requirements of our clientele, and the demands of our climate.

The Bespoke Process

A true bespoke process requires time to be invested, not only by the tailor, but by the customer as well.

Much pleasure can be had in carefully selecting cloths, trimmings and elements of style, or if a customer is short of time this stage can be conducted efficiently with our expert guidance.

A customer must allow for at least four visits the first time we make for them, spanning initial consultation, to final delivery.

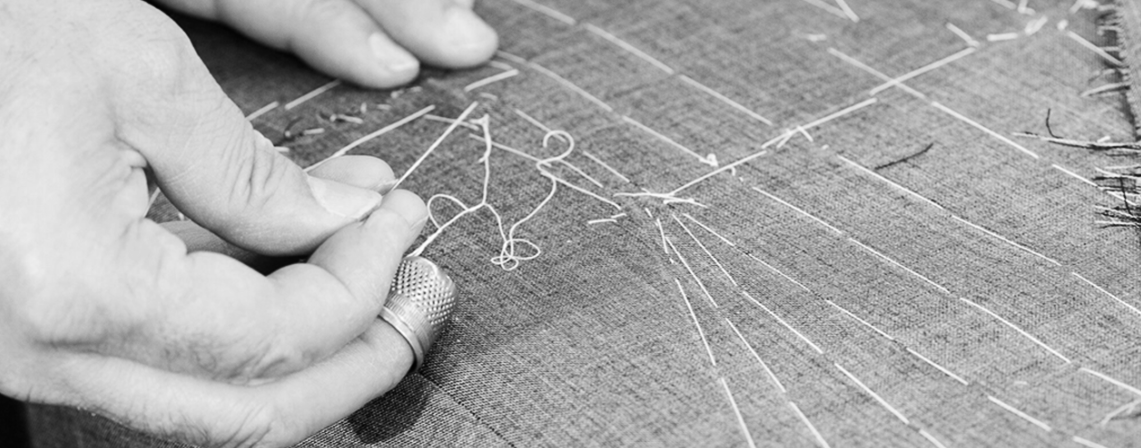

Measurements are taken meticulously and used in drafting a hand cut pattern, which is updated after each fitting.

As a result, subsequent orders require fewer visits. This is where convenience is added to

the list of benefits bespoke tailoring can bring.

Establishing the Foundations

Refining the Details

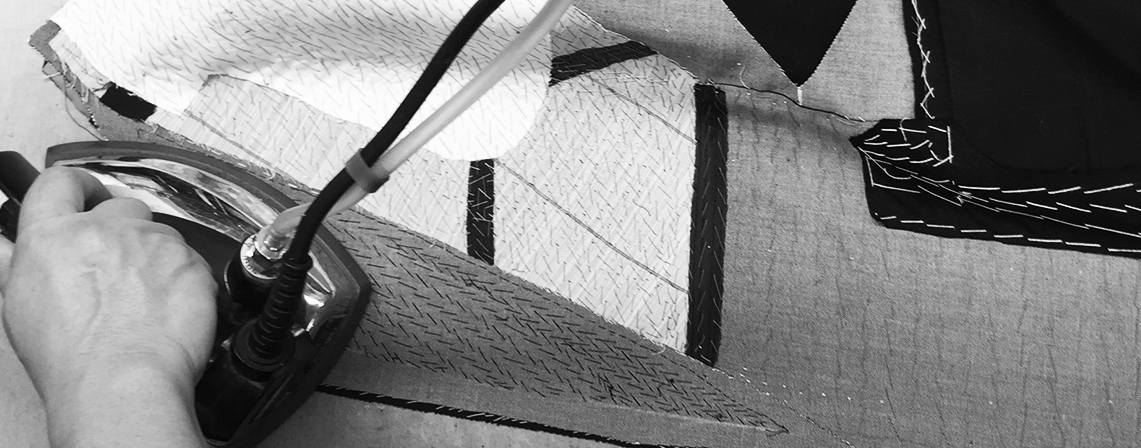

A 16-pound iron is used continuously throughout the making of a coat from the moment the cut pieces arrive on the tailors work bench.

Steam, weight and heat set the shape of the fabric and interior components of a bespoke coat as they are expertly worked by the craftsman.

When the coat is finished the final stage before it finds the shoulders of its new owner involves an hour or more of methodical and precise pressing by the tailor, to ensure that the contours and volume in the garment are retained.

From initial consultation to final delivery of a bespoke commission, John Cutler OAM and his team will invest more than 70 hours. It is work that cannot be hurried, yet is well worth the wait.

J. H. Cutler’s creations are designed to identify with their owners, and given the care they deserve, can and often do, last a lifetime or more.

J.H. CUTLER EST 1884

With a wealth of knowledge and expertise from four generations of genuine bespoke tailoring, we create timeless sartorial goods that are exclusively hand-made for each individual customer, with the finest artisanal craftsmanship.